ePlan parts database is at the heart of each ePlan project and it is also at the heart of ePlan’s database-centric approach to CAD.

Basic principles

So what are the project parts?

Project parts represent all mechanical, electrical, electromechanical devices, assembly parts, equipment, which compose the output of the project. For example a complete air handling unit, or part of the heating automation system, etc.

All project parts have some properties that have to be taken in the consideration, like the ordering information, the size, the nominal power consumption, the power loss due to dissipation, documents with operation instructions and other. Most of them have also some kind of graphical representation inside the project in form of a symbol or more of them combined into a Macro.

Why is a parts database useful?

As we can see a lot of data can be associated to a single product. This means also a lot of time spent on research, understanding and inserting the needed information. I can spend to insert a single part from scratch anything between 15 minutes and several hours if the complexity of the part or unavailability of the information requires extensive research.

In a project with 300 different (unique) parts this can result in a time-consuming and thus expensive process.

Most of the parts tend to repeat themselves during a project and between different projects so being able to reuse all this information over and over again is very handy. Especially if the information is stored in a structured way that enables us simple access and fast search.

Work is simply more efficient if we can easily exchange data with our coworkers and clients.

The obvious solution to this is the use of a dedicated parts database.

What are the advantages of using a parts database?

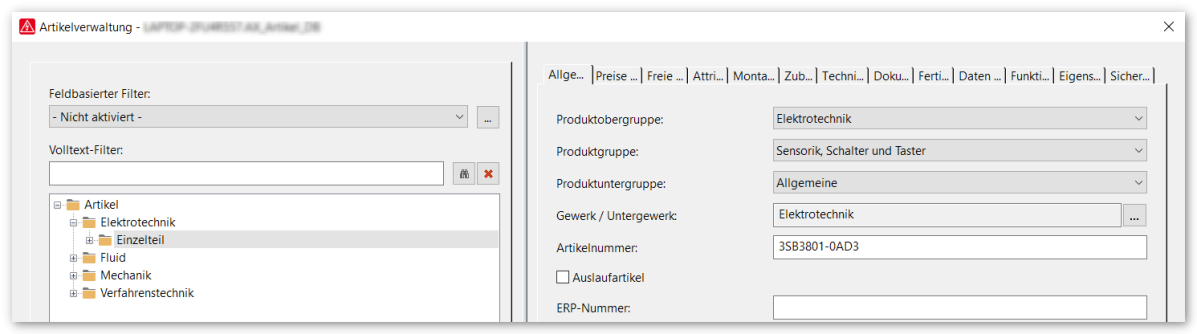

A parts database gives us a coherent structure for classification of parts. It enables easy sorting and search of the needed information. It also gives coherence to the parts information itself, thus enabling us to reuse the same reports and design macros again and again between different projects. It also enables us interchangeability of the inserted data.

Interoperability between projects

In practice it means that we can insert a Part (for example a temperature sensor) for use in project “One”, easily reusing the information in the same project just by citing corresponding the ID of the Part database entry. Then we open a completely new Project “Two” and reuse the Part data again just by citing the part’s database ID.

Real time information exchange with the team

And there is even more… what if we invite a colleague to help us on the project? Nothing easier. We just export the parts he needs from our database and he can easily import them in his own database. An option is also sharing with him the complete database of ours and thus enabling the simultaneous work on the same set of data.

Advanced reports and data elaboration with external software

We can also use the parts database in conjunction with the different data export options. An useful example is the calculation of the heat dissipation inside the cabinet. This information is needed to correctly size the cooling system of the cabinet. As we have the same data structure for each part in the project and between different projects, it is easy to export the information into apposite excel tables and create the report with all needed calculations in few simple steps and later reuse the same tables for other projects/clients.

Seamless interoperability between different ePlan data modules.

Another example is the interoperability of data between different ePlan modules. So a part, defined in the preplanning module, can be seamlessly transfered to, for example, P8 or Fluid or any other way around.

Import of data from external sources

An enforced and coherent data structure has also a very nice implication, that is, any data created by any source can be reused in a coherent way. If a producer creates a part’s information that can be imported in the ePlan parts database, we can easily use it.

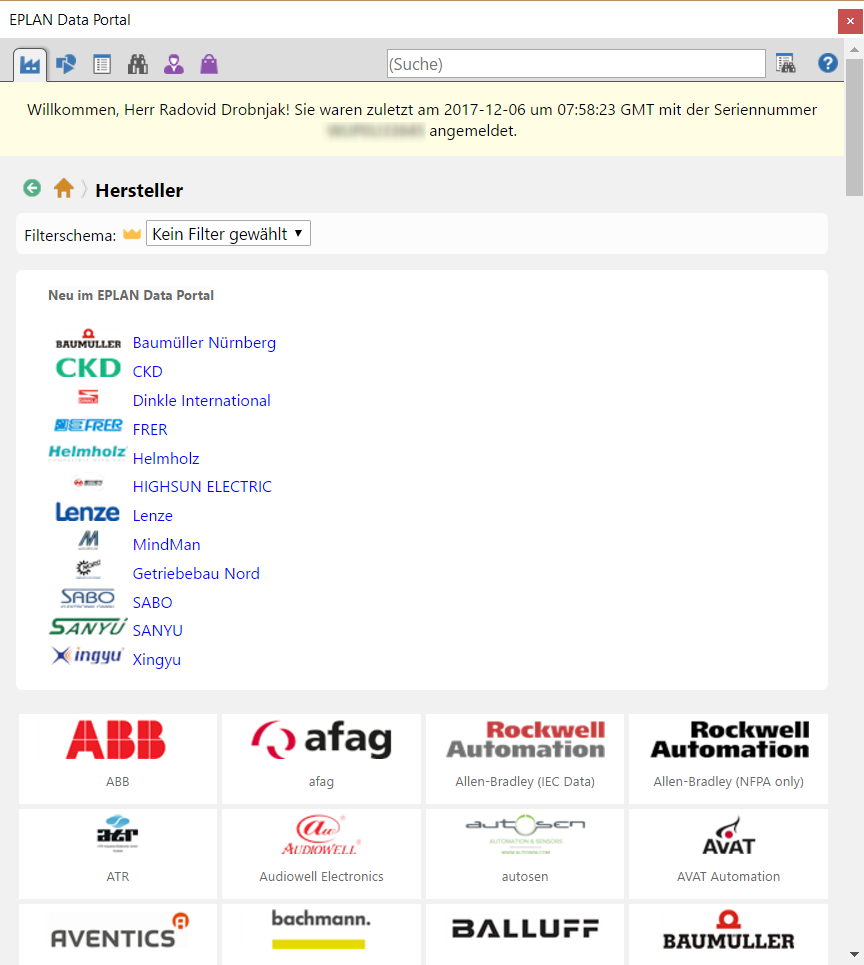

This implies that big Parts databases can be created with a selection of a variety of parts to be imported. For example, Siemens Industry Mall provides importable files for specific parts that can be imported in our own parts databases. ePlan itself provides a very rich parts database named EPLAN Data Portal. The last deserves a separate article, so stay in touch 😉

Some of the licenses and/or subscriptions that were used to create this content, are sponsored by:

Conclusion

The ePlan parts database is an useful tool to store, reuse and share all kind of parts we might have created or will create during our work on ePlan projects. It enables us to create complex reports and data export files which can be reused on and on, regardless of the origin of the entry data. And thus proves itself to be a great time saver.

If you have any comments or questions, please let me know in the comment section below.

2 thoughts on “ePlan parts database”